SHEET METAL

Build your product fast

Stamping and bending

Services

Want to build metal part fast and cost effective?Sheet metal is the way you should know!!

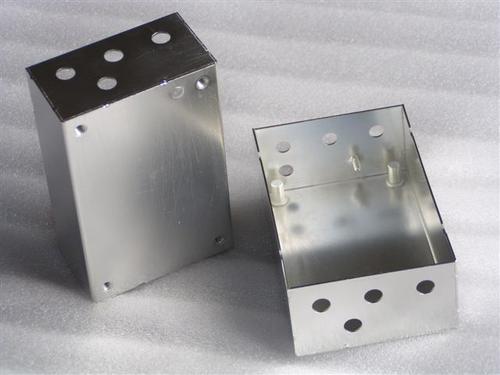

Sheet metal stamping is another fast and economical product manufacturing solution provided in Junjia. Bending, stamping,laser cutting, welding are all available.

Bending is one of the most common sheet metal fabrication operations. Also known as press braking, flanging, die bending, folding and edging, this method is used to deform a material to an angular shape.

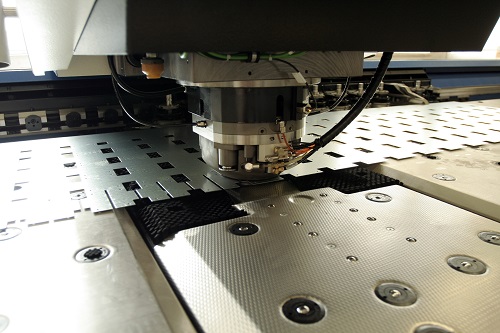

Stamping (also known as pressing) is the process of placing flat sheet metal in either blank or coil form into a stamping press where a tool and die surface forms the metal into a net shape.

Welding is the process by which two pieces of metal can be joined together. There are a number of different welding methods, including spot welding, metal inert gas (MIG), and tungsten inert gas.

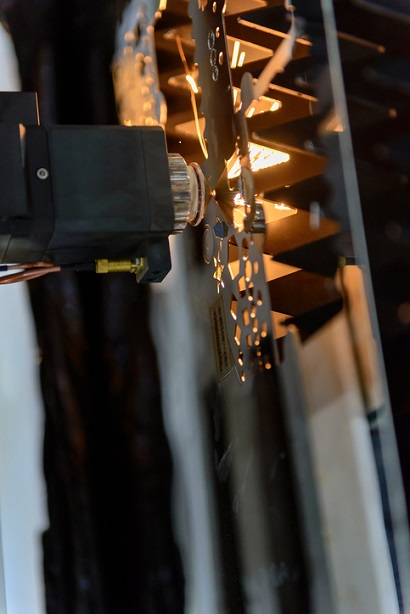

Laser cutting is a technology that uses a laser to slice materials. The focused laser beam is directed at the material, which then either melts, burns, vaporizes away, or is blown away by a jet of gas, leaving an edge with a high-quality surface finish.

Advantages of Sheet Metal Fabrication

1 Material selection

Aluminum + , copper, stainless steel + , steel and zinc

2 Finishing options

Bead blasting, anodizing, plating, powder coating and custom finishes

3 Thickness options

Variety of gauges available

Industries That Use Sheet Metal Fabrication

Some industries that are heavily reliant on sheet metal fabrication are the farming, railroad, aerospace, automobile, pharmaceutical, oil and gas, electronics, food service, heating and cooling, plumbing, medical, telecommunications, computer, military, storage, and construction industries, to name just a few. All of these industries are reliant on precision sheet metal fabrication processes for products and services.